Check Valve

Check Valve

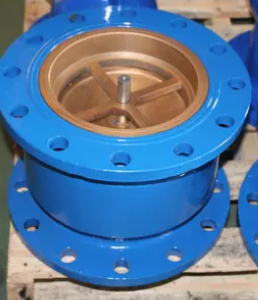

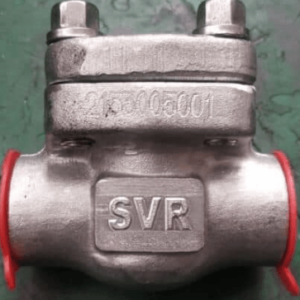

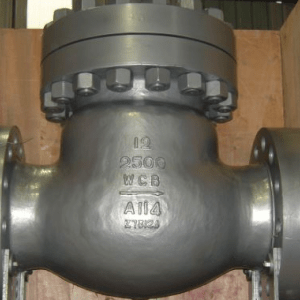

African Valve is a dependable Check Valve Supplier in Algeria, offering robust non-return valves that ensure unidirectional flow in piping systems. Our check valves are engineered to prevent backflow and protect pumps, compressors, and pipelines from reverse pressure damage. With a variety of types, sizes, and materials, we cater to both low-pressure and high-pressure applications across critical industries.

Function & Working

Check valves operate automatically, opening with forward flow and closing under reverse flow pressure. They rely on differential pressure and gravity or spring-assisted mechanisms to shut the valve disc, ensuring seamless non-return functionality without manual operation.

Advantages

-

Prevents backflow and equipment damage

-

Operates without external actuation

-

Minimizes water hammer in pipelines

-

Compact and easy to install

-

Suitable for both vertical and horizontal mounting

Types Offered

-

Dual Plate Check Valve

-

Single Plate Check Valve

-

Lift Check Valve

-

Non-Slam Swing Check Valve

-

Pressure Seal Swing Check Valve

-

Tilting Disc Check Valve

-

Swing Check Valve

-

Forged Steel Swing Check Valve

Industries Served

-

Oil & Gas

-

Petrochemical

-

Water Treatment

-

Marine and Offshore

-

Power Generation

-

HVAC and Utility Networks

Key Components

-

Valve Body – Built from durable alloys for corrosion and pressure resistance

-

Disc/Plate – Moves freely or spring-loaded to allow or block flow

-

Seat Ring – Machined for bubble-tight sealing

-

Hinge Pin or Guide – Ensures precise disc movement

-

Spring (if applicable) – Assists rapid closure to prevent water hammer

-

Bonnet – Provides access for maintenance

Technical Specifications

-

Design Standards: API 594, ASME B16.34, BS 1868

-

Body Materials: WCB, CF8M, CF3M, WC6, Bronze, Super Duplex, Monel, Alloy 20, Ductile Iron

-

Trim Options: SS304, SS316, Stellite, Monel

-

Pressure Ratings: Class 150 to 2500 / PN10 to PN160

-

Size Range: DN15 to DN1200

-

End Connections:

-

Flanged (RF or RTJ – Raised Face or Ring Type Joint)

-

Butt Weld (BW – permanent weld for high-pressure lines)

-

Socket Weld (SW – compact welds for small diameter piping)

-

Threaded (NPT – National Pipe Thread)

-

-

Actuation Options: Not required (self-acting design)

-

Special Features:

-

Non-slam design to reduce shock and vibration

-

Optional soft seats for enhanced sealing

-

Fire-safe and corrosion-resistant variants

-

Engineered by a certified Check Valve Supplier in Algeria

-

-

Swing Check Valve1 Product

-

Non Slam Swing Check Valve

$232.00 – $477.00 This product has multiple variants. The options may be chosen on the product page

Showing all 9 resultsSorted by price: high to low