Need help?

| No attributes available |

Body: Titanium TA1, TA2, TA10, TC4, GR2, GR3, GR5, Duplex Stainless Steel, Super Duplex Stainless Steel, Alloy

20, CN7M, Hastelloy, Carbon Steel, WC6, WC9, C5, C12, LCB, CF3M

Disc: Titanium TA1, TA2, TA10, TC4, GR2, GR3, GR5Duplex Stainless Steel, Super Duplex Stainless Steel, Alloy 20,

CN7M, Hastelloy, Carbon Steel, WC6,WC9, ?C5, C12, LCB, CF3M

Trim: Incoloy 800, Incoloy 800H, Incoloy 825, SS304, SS316, SS304L, SS316L, 13%Cr.Steel, Stellite, Hastelloy,

Alloy 20, Duplex Stainless Steel, Super Duplex Stainless Steel

Gland Packing: Graphite, PTFE

Nominal Size: 2″ to 24″

Nominal Pressure: PN 1.0 to 25 Mpa, Class 150 to Class 2500

Temperature: -198?c to +450?c

Design and Manufacture: ANSI B16.34, API 600, API 6D, API 603, BS 1414, BS 5352, DIN 3352

Face to face (end to end): ANSI B16.10, API 6D, ASME B16.10, EN 558, DIN 3202

Flanged connection: 2? to 24? , ANSI B16.5, 26? to 36?,? MSS-SP-44 to API605

Test and inspection: API 598, API 6D, DIN 3230

Butt welded end: ANSI B16.5

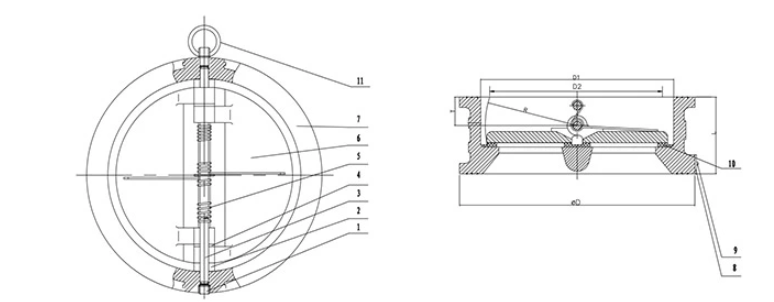

| Size | D | D1 | D2 | L | R | T |

| 2″ | 102 | 65 | 32 | 54 | 29 | 25 |

| 2.5″ | 121 | 78 | 42.1 | 60 | 36 | 29.3 |

| 3″ | 134 | 94 | 82 | 67 | 43.4 | 27.7 |

| 4″ | 171 | 117 | 97.5 | 67 | 55.6 | 26.7 |

| 5″ | 193 | 145 | 111.8 | 83 | 67.6 | 38.6 |

| 6″ | 219 | 171 | 127 | 95 | 78.6 | 46.3 |

| 8″ | 276 | 222 | 161.7 | 127 | 104.4 | 66 |

| 10″ | 336 | 276 | 213.4 | 140 | 128 | 70.7 |

| 12″ | 406 | 327 | 237.9 | 181 | 156.7 | 102 |

| 14″ | 448 | 375 | 312.2 | 184 | 179.8 | 89.2 |

| 16″ | 511 | 416 | 351 | 191 | 198.4 | 92.5 |

| 18″ | 546 | 467 | 409 | 203 | 226.2 | 96.2 |

| 20″ | 603 | 514 | 451.9 | 213 | 248.2 | 102.7 |

| 24″ | 714 | 616 | 554.7 | 222 | 297.4 | 107.3 |